Mexican field trial shows clear potential for hatcheries to improve their bottom line

Due to seasonal temperature changes, Mexican shrimp hatcheries need to produce 70% of the national PL demand between March and June, so grow-out farms can focus their culture on the summer. For the hatcheries, this means achieving high volumes through large production capacity, increased stocking density, faster growth, and the implementation of a two-culture phase system.

A recent field trial conducted by INVE Aquaculture shows that an optimized feeding protocol can help hatcheries get the most out of their 4-month season thanks to a 27% increase in PL production and a 20% higher profitability.

Average body weight as key performance indicator

In Mexico’s standard two-culture phase system, the first phase covers nauplii stage 4-5 to post-larval stage 6 (PL6), and the second phase covers PL6 to PL12 (harvest stage). Average body weight samples taken upon transfer from phase 1 to 2 indicate that substantial improvement of this important culture parameter is possible.

Hatchery trial with INVE’s ‘Best Balance’ feeding protocol

The objective of the trial in a commercial hatchery in Sonora state, Mexico, was to evaluate the productive and cost-benefit performance of INVE’s ‘Best Balance’ feeding protocol in comparison with the local standard hatchery protocol. Part of the tanks was fed according to the hatchery’s standard protocol. The other tanks were fed according to INVE’s Best Balance protocol. Other aspects of the culture management such as water treatment and microalgae cultivation were kept in line with the hatchery’s standard procedures.

“Although larval development and growth can be positively impacted by factors such as genetic improvement of breeding lines, stocking density, and water management, optimized nutrition still seems the obvious solution. That is why we set up a trial to investigate if a carefully balanced feeding protocol could add effectiveness to the larval rearing stages, allowing hatcheries to produce more, faster growing, and stronger post-larvae.”

Importance of Artemia

The hatchery standard protocol used different types of feed and brands (liquid diets, microparticles feed, and flakes) as well as additives, multivitamins, and probiotics from different commercial manufacturers. Regular EG type of Artemia cysts were used, and traditionally harvested using a double mesh to separate the nauplii from the empty cysts, and hot water (75°C) for disinfection.

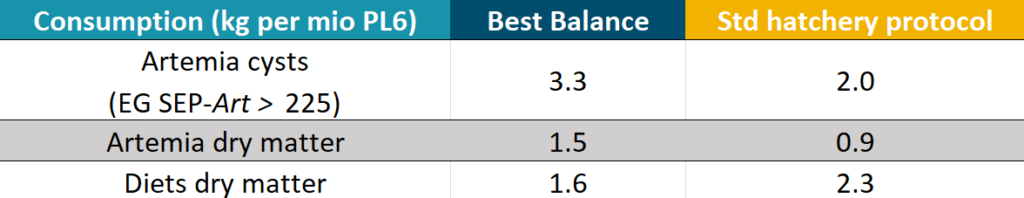

As shown in Table 1, INVE’s Best Balance protocol included 68% more Artemia and 28% fewer diets on dry matter basis.

Table 1: Overview of Artemia and diet consumption for the Best Balance and the Std hatchery protocol.

More concretely, the protocol included the following INVE products:

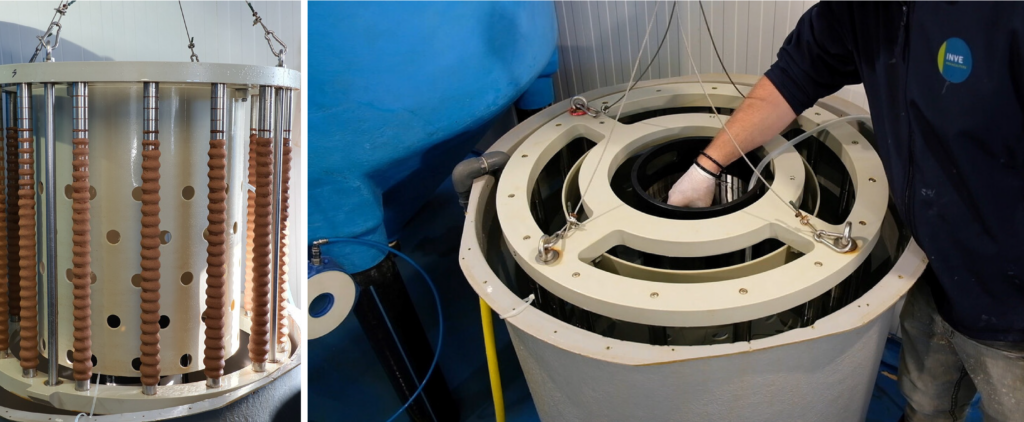

- EG SEP-Art cysts 225 Knpg, hatched according to the IFU and the nauplii separated from their shells and cysts using INVE’s SEP-Art CysTM 2.0 tool. This equipment consists of 16 magnetized bars that retain the cysts and empty cyst shells, keeping the nauplii in the suspension without damaging or injuring the nauplii (Figure 1) and maintaining the feed quality.

- FRiPPAK® FRESH diets (#1 CAR, #2 CD, #3 CD) and FRiPPAK® PL+ ULTRA diets (PL+150, PL+300), and health booster diet Sano S-PAK (0/2). FRiPPAK® FRESH diets contain microencapsulated particles to keep the nutrients from leaching into the water. Appropriate particle size in function of the stage is crucial e.g., for zoea stages the size should be below 50 µm for optimal ingestion.

- Sanolife® MIC and Sanolife® PRO-W were used as probiotics and Sanocare® FIT as a water conditioner.

Figure 1: INVE’s CysTM 2.0 equipment uses magnetized bars to separate the empty cyst shells without damaging the nauplii.

“The Best Balance protocol draws its beneficial effects from a substantial increase in the amount of Artemia used. But the impact on the hatchery team’s workload remains limited thanks to INVE’s SEP-Art tools, which drastically simplify the Artemia harvesting process.”

Technical results

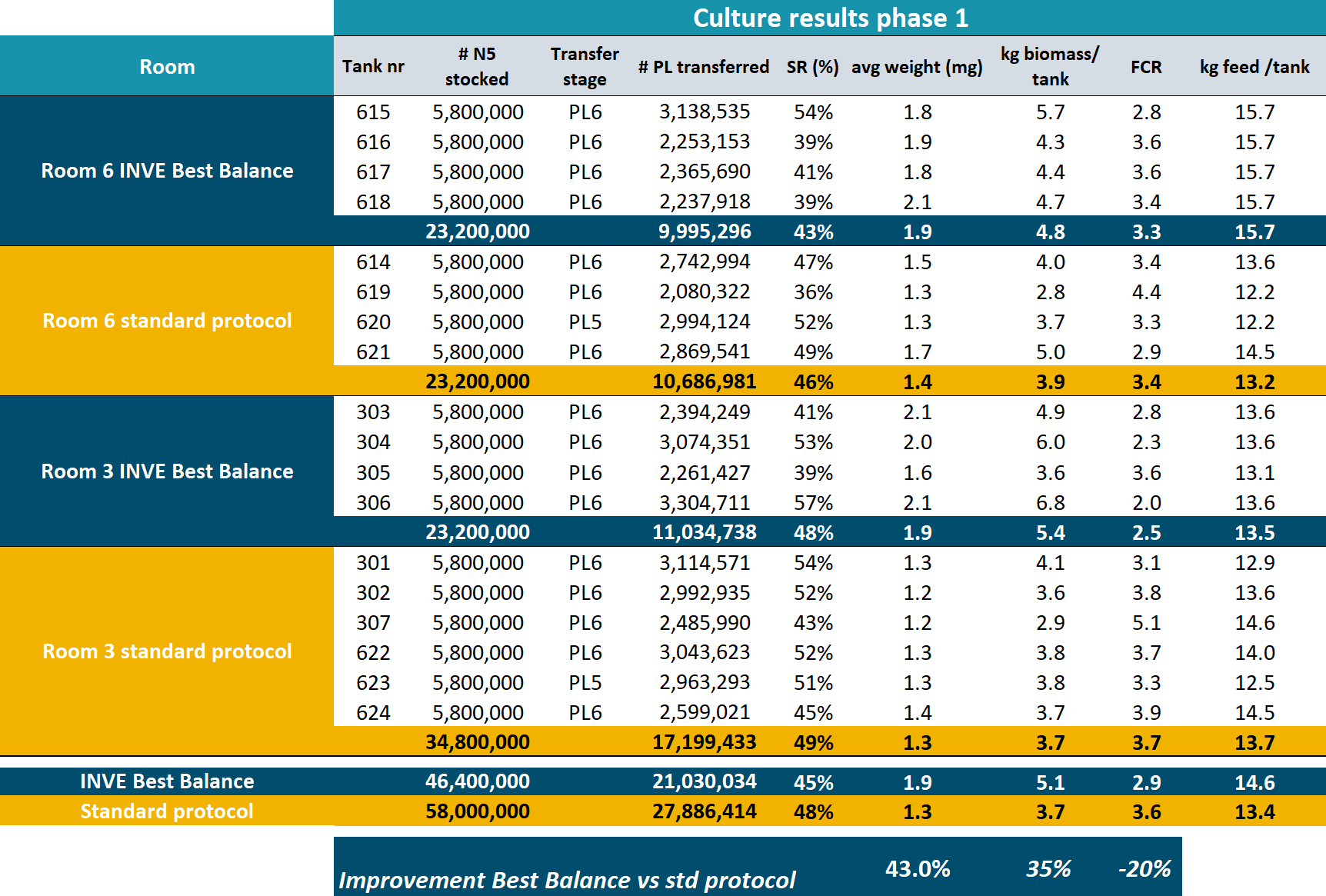

As shown in Table 2 below, the observed results at the end of the first larval rearing phase demonstrated a clear impact on growth, biomass reached per tank, and feed conversion rate. Compared to the standard hatchery protocol, INVE’s Best Balance protocol resulted in similar survival, but with higher average PL body weight (+43%), higher tank biomass (+35%) and a 20% more efficient FCR.

Table 2: Results of the main technical indicators evaluated in the trial. The stock was carried out in modules 3 and 6 using 30 m³ concrete, lined tanks. In module 6, tanks 15, 16, 17 and 18 were fed according to INVE’s Best Balance protocol (INVE BB), and tanks 14, 19, 20 and 21 followed the hatchery standard protocol (std protocol). Module 3 was stocked one day later, with INVE BB tanks 3, 4, 5, 6 and std protocol tanks 1, 2, 7, 22, 23 and 24.

Evaluation of growth

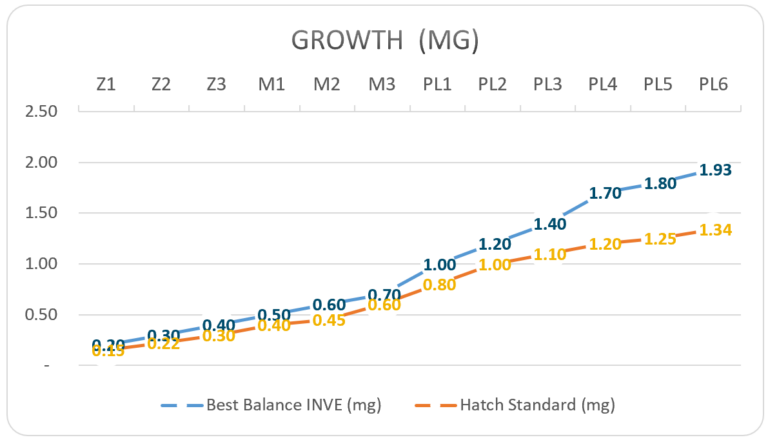

Growth was evaluated through daily body weight evaluation from PL3 onwards using the LarvIA application, previous values were estimated according to the trend (Figure 2).

Figure 2: Average body weight (mg) for INVE’s Best Balance protocol as compared to the Standard Hatchery tanks

Profitability at the hatchery’s operational level

Post-larvae cultured under INVE’s BB protocol reached transferable size in 12 days (1.4 mg/PL3), while it took 15 days under the standard protocol (1.3 mg/PL6).

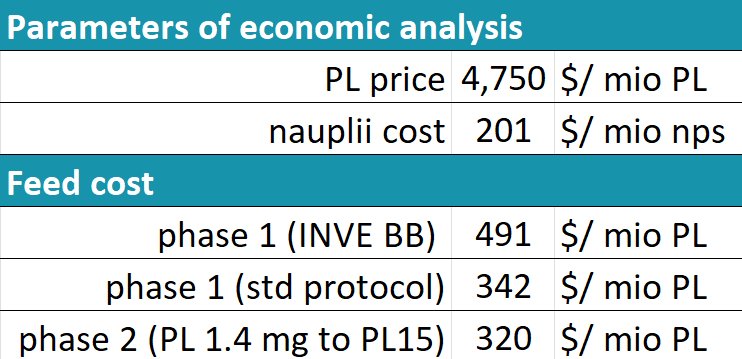

Table 3: Summary of the income (PL price) and cost estimates in support of the economic analysis. Feed cost estimates resulted from the INVE BB – standard protocol trial (15 days of culture).

A shorter phase 1 culture period not only brings the opportunity to run more production cycles per season, but also enhances the survival rate.

Considering a 4-month season, this implies 8 cycles with the standard protocol versus 10 with INVE’s BB protocol. This means a 27% increase in PL production, e.g. from 1 mio to 1.27 mio PL produced.

The consequent additional revenues far outweigh the extra costs linked with increased PL production (nauplii cost, phase 2 feed cost) and the additional feed cost of INVE’s BB protocol during phase 1 (Table 3).

Table 4 summarizes the economic analysis of the hatchery’s standard protocol versus INVE’s BB protocol and concludes on an increased profitability of 20%.

Table 4: Economic analysis illustrating how INVE’s BB protocol unlocks operational profitability through shorter but more culture cycles per season.

Conclusion

- The use of INVE’s Best Balance protocol in phase 1 of the hatchery culture cycle increased PL size and harvestable tank biomass and improved the feed efficiency.

- The higher inclusion of Artemia was the main driver for increased growth.

- Increased PL size allows for more cycles per season, and thus a higher seasonal PL production.

- INVE’s Best Balance protocol unlocks the hatchery’s production potential and increases the hatchery’s profitability.

- Best Balance aims to deliver robust post-larvae that maintain their high-quality during grow-out.

Note: Best Balance is not a fixed protocol, but an approach to shrimp hatchery culture in which the use of high-quality products is adjusted to local culture conditions. For customized technical support contact us via our dedicated customer support platform: