Don’t fall behind: stay up to date with how technology is redefining live food management in the hatchery.

The cost-efficient production of live food such as Artemia and rotifers remains one of the crucial success factors for fish and shrimp hatcheries worldwide. This is why a growing number of hatcheries rely on the latest technologies to streamline their live food management. By moving away from traditional harvesting methods (e.g. double sieving or chemical decapsulation of Artemia cysts), more and more hatcheries are embracing safer, more efficient, and more sustainable ways to get the most Artemia out of every euro/dollar spent.

New and better ways to harvest Artemia

The key to harvesting Artemia is getting a maximum number of viable nauplii and efficiently separating the nauplii from the empty cyst shells. One of the most significant developments in this regard has been the introduction of SEP-Art technology. Thanks to the application of a unique magnetic coating to Artemia cysts, hatcheries can benefit from a simplified and efficient way to harvest their live food.

How does SEP-Art Technology work?

Our patented SEP-Art technology allows hatcheries to treat Artemia cysts with a non-toxic magnetic coating. This makes it possible to collect the nauplii and separate them from their cyst shells far more easily using specially designed magnetic tools. The process is faster, more efficient, and significantly reduces the labor involved in food recovery.

1. Improved cost-efficiency and sustainability

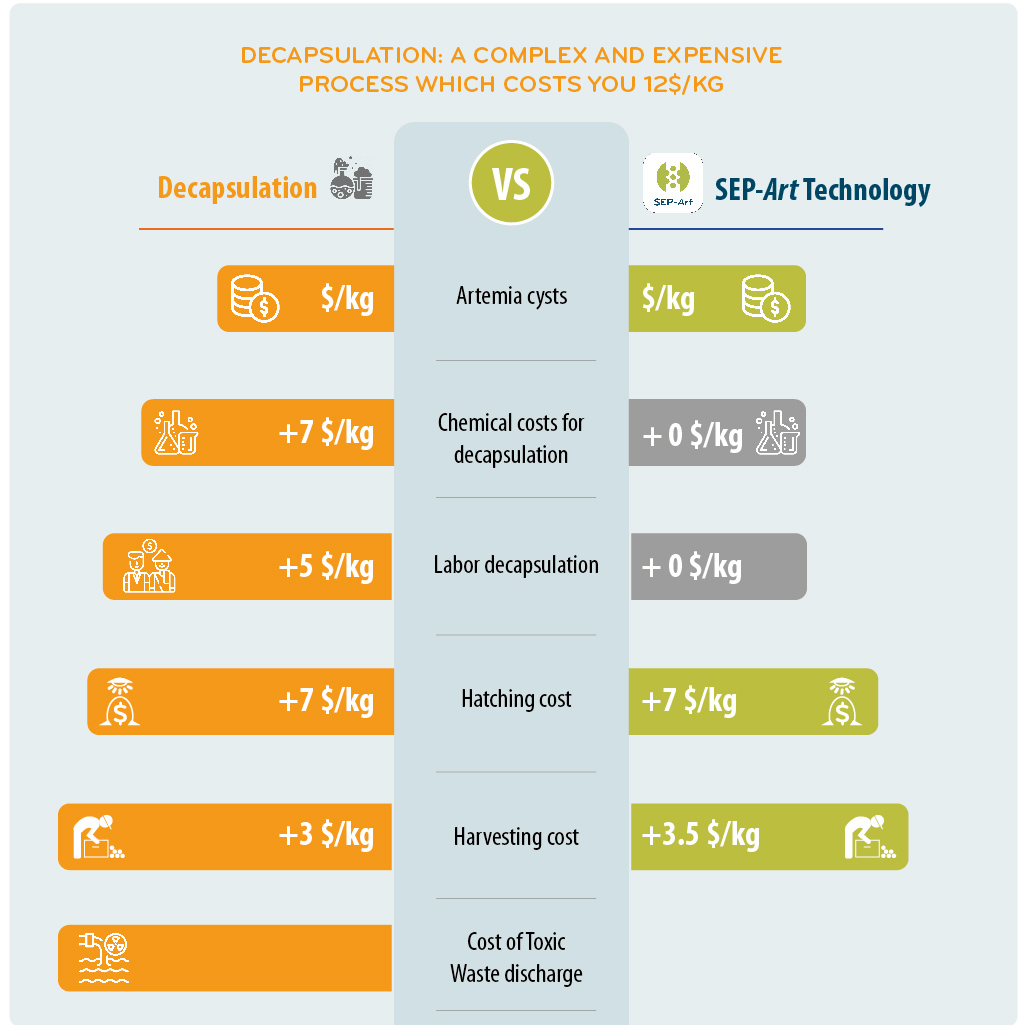

- SEP-Art decreases the operational costs linked to producing Artemia nauplii significantly. Compared to the decapsulation method, up to 10$/kg of product can be saved (no need for chemicals and reduced labor).

- It reduces the amount of remaining empty shell material, and thus improves the biosecurity in the larval tanks (less risk of bacterial load, e.g. Vibrio).

- It reduces the risk of gut obstruction or failed ingestion caused by empty shell material.

- It is better for the environment because it eliminates the use of hazardous chemicals, the discharge of waste or by-products, and the accumulation in the food chain.

2. Safer, simpler, and more comfortable work

- SEP-Art eliminates the use of hazardous chemicals and the release of toxic fumes or gasses during the Artemia harvesting process.

- The SEP-Art method maximizes the recovery of the hatching output and speeds up the harvest and collection of the nauplii thanks to specially developed and easy-to-use magnetic tools.

SEP-Art AutoMag is a fully automatic tool that was especially designed to harvest medium to large hatching volumes (up to 15 kg of SEP-Art cysts) with minimal labor input and maximum biomass outcome. The system can be connected to the Artemia hatching tank and has integrated piping for clean sea water, air, and oxygen. As the hatching tank is emptied into the AutoMag, the built-in magnets capture the magnetized cysts and empty shells while the nauplii are instantly concentrated and rinsed. The result: a dense and clean suspension of pure nauplii only. The self-cleaning system of the AutoMag evacuates the collected cysts, leaving clean magnets for the next batch of Artemia.

The AutoMag’s fully automated process allows fast harvesting: typically, a 5-ton hatching tank (10 kg of EG SEP-Art 240 cysts hatched at a density of 2 g/l), is handled in less than an hour. Similar SEP-Art tools are also available in manual (SEP-Art HandyMag) y semi-manual (SEP-Art CysTM 2.0) versions, tailored to the needs of different hatchery sizes.

The SEP-Art technology drastically improves the quality of live food. By simplifying the harvesting process, maximizing the output of high-quality live food, and reducing risks by preventing unwanted material from being transferred to the larval tank, it plays a crucial role in facilitating a more predictable and standardized post-larvae (PL) and fry production. In addition, the Artemia SEP-Art tools are a sustainable solution designed to maintain quality nauplii, reduce losses and ensure safety for workers and the environment. These benefits establish SEP-Art cysts as an indispensable tool in modern hatchery practices.

Embracing the Future of Feed Management with automated, AI-powered live food quantification

During Aquaculture Europe in Vienna, we introduced yet another leap forward in aquaculture technology. Together with Aris, we have developed SnappArt: a revolutionary AI-powered live food counting device that automates the quantification of rotifers and Artemia. The project was supported by Eurostars, a European funding instrument for collaborative R&D and innovation projects.

The end of manual inspections

Until now, the adequate production and quality control of Artemia and rotifers demanded meticulous manual inspections. These labor-intensive and error-prone procedures conducted on limited sample sizes often lead to inconsistent feed administration. Moreover, skilled staff is hard to find, and sampling methods are not globally standardized. All the above too often jeopardizes the predictability of high-quality shrimp and fish production. Representing a monumental shift in live food quantification, SnappArt replaces conventional manual counting with a method that requires far less time and effort while offering unparalleled precision. This ground-breaking technological innovation propels hatcheries towards more time- and cost-efficient, sustainable, and consistent live food production.

Easy-to-use device with advanced AI-driven software

Designed with advanced computer technology, the SnappArt device looks deceivingly modest. The real innovation, however, lies in the AI-driven image analysis software that ensures rapid, precise analysis of samples. And a highly intuitive user interface makes the device remarkably easy to operate.

When implemented in the fish or shrimp hatchery, SnappArt revolutionizes the assessment of Artemia and Rotifer quality, ensuring consistent and reliable results. With reduced inspection time and data-driven decision-making, hatcheries can boost their profitability, optimize growth ratios, and improve their overall production efficiency.

This innovative tool is set to rapidly become a must-have for any hatchery wishing to ensure the consistency and reliability

of their production practices thanks to:

- Speed and efficiency: The automated tool swiftly processes large volumes of samples, significantly reducing counting time

and freeing up valuable human resources. - Accuracy and consistency: By eliminating the inherent subjectivity and variability associated with manual counting, the AI-based tool provides highly accurate and consistent results, ensuring precise feed management.

- Data tracking and analysis: The tool generates comprehensive data reports, enabling hatcheries to monitor live food, and optimize live food utilization strategies.

- 24/7 access to expertise: Automation of the counting process reduces tedious but very important labor, saving both time and costs for hatcheries. At the same time, the device relies on expert knowledge that is accessible to the hatcheries 24/7, securing and standardizing knowledge year-round.

Conclusion:

With the introduction of SEP-Art technology and the SnappArt counting tool, the aquaculture industry is on a new path toward more streamlined, efficient, and sustainable hatchery practices. By simplifying the recovery process, improving the quality of live food, and introducing a reliable counting method, these innovations are pushing the boundaries of what is possible.

These technologies represent the industry’s commitment to continuous improvement, innovation, and sustainable practices. With the rapidly increasing adoption of innovations such as these, the aquaculture industry continues to grow profitably and sustainably while meeting the world’s increasing demand for seafood.

More information about SEP-Art and SnappArt

This article has been published in the following Magazines