The revolution of Artemia as live: A review of the new technologies for Artemia production

Constant evolution is the only way of supporting the industry sustainably. INVE Aquaculture has developed technologies for using Artemia cysts in fish and shrimp hatcheries, including tools, formulations, and processes, which provide cleaner, environmentally friendlier, and more efficient alternatives for aquaculture.

Currently, most Artemia used in aquaculture is harvested from the Great Salt Lake in Utah and in Central Asia, and China.

Throughout the last 38 years, INVE Aquaculture has been developing technologies for using Artemia cysts in fish and shrimp hatcheries in the most optimal ways. Some of its achievements include diapause termination, which is the dormancy state of cysts in nature, and with this maximizing hatching output.

Bioencapsulation is another development that was introduced by INVE, allowing hatchery managers to enrich live food to the optimal nutritional value by adding certain essential nutrients and micronutrients, to improve larval development of fish and shrimp larvae. Although it is not common practice in larval shrimp, it is part of the standard protocol in hatcheries of marine fish larvae.

New Technologies

Currently, there are three technologies available: SEP-Art®, D-FENSE and SMArt, each one focusing on a specific solution (learn more here).

SEP-Art®

Even the best quality Artemia cysts are sensitive to how they are handled during hatching, harvesting, and decapsulation. The key to harvesting Artemia is getting a maximum number of viable nauplii out of their cyst, and efficiently separating the nauplii from the empty cyst shells. This can be a hard task when done the ‘old’ or traditional way. Innovative techniques such as INVE’s patented SEP-Art® technology offer you a solution and several benefits:

- Improved cost-efficiency

- Simplified work

- Safer and more comfortable work

- Better for the environment (as compared to the decapsulation or double sieving process).

As an ideal complement to its innovative SEP-Art® Artemia cyst coating, INVE has developed a comprehensive set of Artemia SEP-Art® Tools, designed to maintain nauplii quality, reduce losses and ensure safety for workers and the environment.

For the past years, the SEP-Art® tools have been continuously improved from initial designs to three next-generation tools: SEP-Art® HandyMag, SEP-Art® CysTM 2.0 and SEP-Art® AutoMag.

The SEP-Art® HandyMag tool is a manual tool that has two magnetic bars to separate the cysts from the nauplii. On the other hand, the SEP-Art® CysTM 2.0 tool is a semi-automatic tool designed for effortless and efficient Artemia harvest relying on 16 magnetic bars connecting to each other via two plastic rings.

Finally, the ®® AutoMag tool is the fully automated Artemia harvesting tool, specially developed for hatcheries aiming to harvest medium to large hatching volumes in an efficient and fully automated way. This machine is composed out of 8 tubular magnets mounted on a rotor that rotates at a speed of 2.4 RPM collecting & removing the magnetized cysts from the tank.

While the separation process takes place, the nauplii harvested in the AutoMag tank can be cleaned and rinsed, thanks to the screen positioned in the tank which keeps the nauplii inside the tank while removing the dirty water.

D-FENSE

D-FENSE technology is a formulation of Artemia cysts developed to control bacterial development during the hatching process increasing the biosecurity levels of the hatchery, by controlling and managing the transfer of microorganism from the live food to the larval tanks. As a result, more consistent larvae production can be achieved.

SMArt

SMArt is another of the processes developed by INVE, in our Artemia area, which has been able to remove light as an essential factor to be controlled for achieving optimal hatching levels. Using a process that modifies Artemia, it reduces the influence of the amount of light in function of the distance, simplifying and maximizing the output of Artemia hatching, because the light is no longer a parameter to be regulated.

Hatching Conditions of Artemia

When outside conditions improve to the point where it is safe for the brine shrimp larvae to come out of their shell, the embryos will respond to a number of triggers and resume their metabolism. They will take up water, start to metabolize and convert their carbohydrate reserves, eventually increasing the osmotic pressure inside the cyst up to the point where the cyst shell bursts and the nauplius, still enclosed in the hatching membrane (also called umbrella stage) is released from the cyst shell. Within the hatching membrane, one can see the nauplius moving its appendages. Within the next hours, the hatching enzyme is secreted in the head region of the nauplius and the free-swimming instar I nauplius is released.

Several elements play a crucial role in this delicate process, that aquaculture professionals need to imitate to optimally hatch Artemia cysts (salinity, aeration, etc,), controlling all these parameters can provide an increase of 10 to 15% in production.

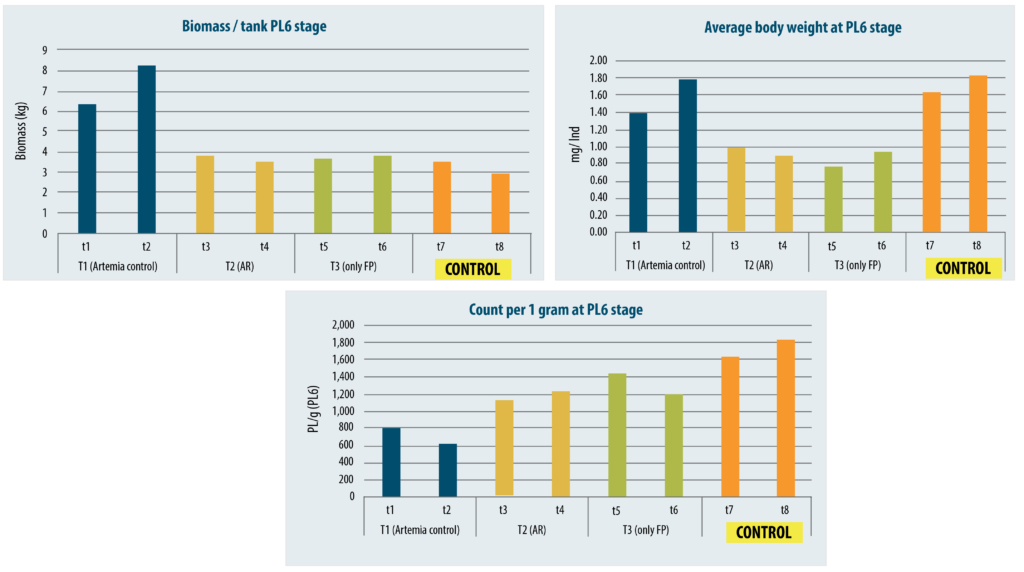

A well-balanced protocol, relying on a sufficient amount of Artemia and high-quality larval diets; will help you to find the ideal balance between cost-effectiveness and quality. The inclusion level of Artemia sp. in daily feeding protocol from mysis up to late PL stage in the hatchery affects positively the growth, survival, PL count, biomass and robustness of the postlarvae.

If the use of Artemia sp. in the larval protocols is optimized, substantial effects can be observed. In the end, the outcome will be stronger and more robust PLs will be produced for the nursery as shown during a test presented below. These results show that the first feed matters and that overall, when better nutritional protocols are being applied in the early stages, stronger and better PLs can be produced.

Conclusions

The new technologies applied to Artemia cysts, allow the production of high-quality Artemia nauplii free of any cysts, relying on technologies that make decapsulation redundant while guaranteeing high biosecurity standards.

The quality of the Artemia nauplii is improved indisputably, resulting in a more consistent and improved output throughout the larval stage.