The world of Artemia cysts as live feeds in marine shrimp hatcheries: insights on current trends in Artemia nauplii production, usage and technologies

In the January/February issue of AquaCulture Asia Pacific, Patrick Sorgeloos (Emeritus Professor at Ghent University), discusses Artemia cysts as live feeds in marine shrimp hatcheries and shared his knowledge of the history, importance, and potential of Artemia in supporting a sustainable aquaculture industry at a webinar organized by NACA (Network of Aquaculture Centres in Asia-Pacific).

In his short introduction, Patrick touched on several fundamental parameters to ensure optimal hatching and preparation of Artemia for use in fish/crustacean hatcheries.

Understanding biology

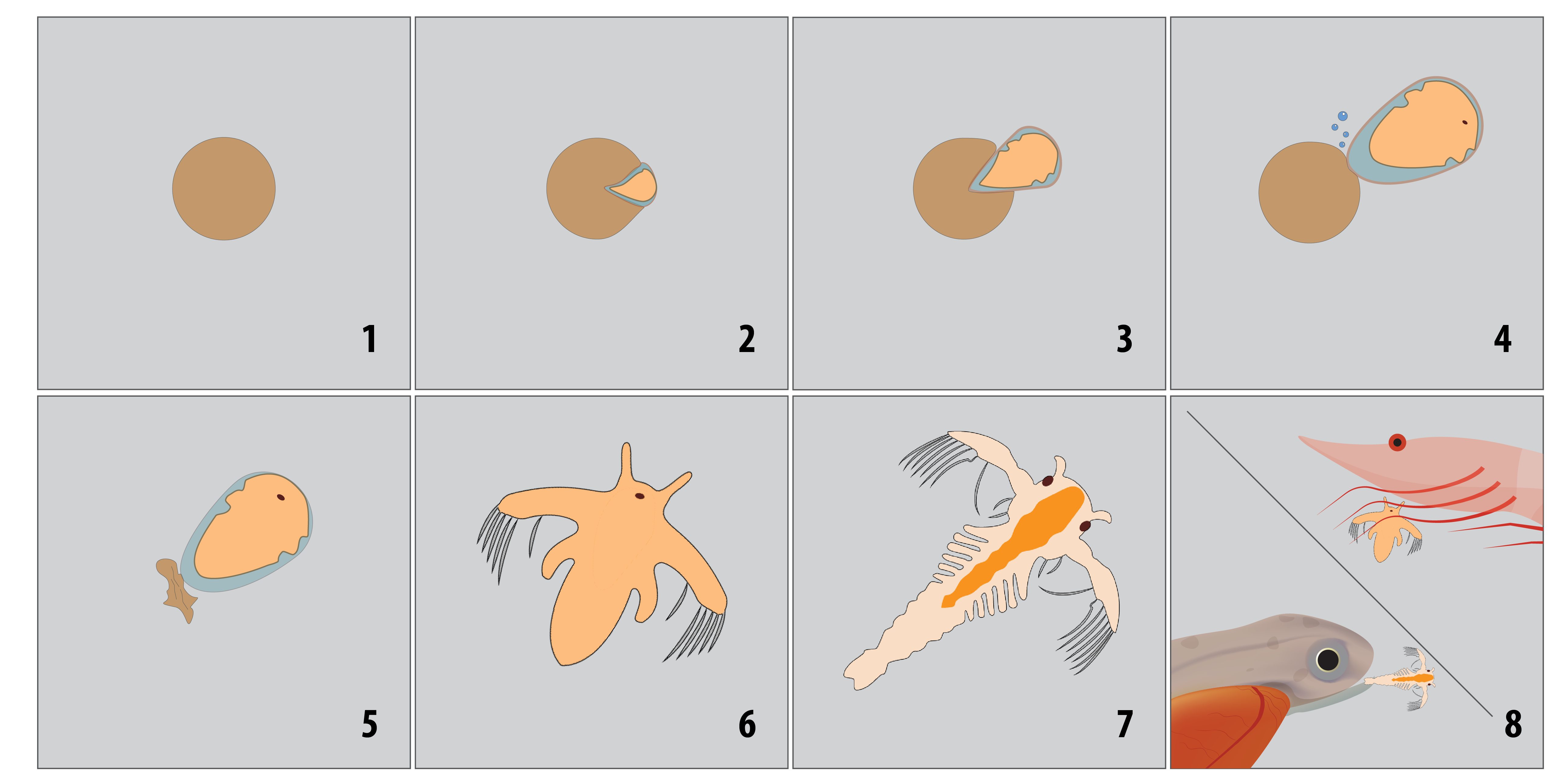

Artemia cysts are dry embryos, commonly referred to as eggs, they are approximately 0.2mm in diameter. Cysts have less than 10% water content but are very hygroscopic. They have zero metabolism but contain viable embryos: upon hydration embryonic development resumes.

Patrick describes how the outer cuticular membrane acts as a molecular sieve. Molecules of oxygen, water and carbon dioxide can go in and out, however, any molecule bigger than carbon dioxide cannot get through this sieve.

“Once fully hydrated, a light trigger resumes metabolism and initiates the carbohydrate metabolism. As a result, trehalose is converted to glycogen and glycerol which accumulate in the cysts. The more glycerol being produced, the more water absorbed, which ultimately results in a pressure build-up. This induces the breakdown of the chorion and the release of the embryo to the umbrella stage. Further incubation will allow the embryo to continue to develop into a free-swimming nauplius. This will subsequently molt into Instar I stage, and then into Instar II stage. All of this can happen within less than 24 hours.”

Patrick added that at the instar II stage, Artemia has an open mouth and a functional digestive system. This means from that moment onwards the animals can start to accumulate small particles through filtering, allowing them to be enriched with nutrients and bacteria.

Hatching synchrony

Sorgeloos also drew attention to hatching synchrony, which represents the speed of hatching of the population; “Synchrony of hatching can be very different from one batch and strain to another. Products with a similar hatching efficiency potential (number of nauplii per gram product) can still differ. This is because they may have a different speed in development or hatching potential. This can be observed by the fact that some of the embryos have developed into Instar I or II, while others are yet to break and are still in the umbrella stage. Maximizing synchrony requires good knowledge of the product and good control of the environmental parameters (light, pH, DO and temperature).”

Rising demand for Artemia

Due to the growth of aquaculture in Asia, Latin America and Europe, the consumption of Artemia cysts has increased significantly, particularly in the main aquaculture producing countries and regions such as China, India, Vietnam, Ecuador, and Europe.

“The key to successful aquaculture lies in the use of Artemia as a live feed in hatcheries in a consistent and cost-effective way to produce high-quality early-stage organisms such as fry, post larvae, crablets. The global yearly consumption of Artemia has increased tremendously, from 1 ton in 1970 to ± 3,000 tons. In the early years, hatcheries were using around 25kg of Artemia cysts to produce 1 million shrimp post larvae but today they have become more efficient and 2 to 5kg of Artemia cysts per million PL are used. In terms of usage, China is the global leader; it is the largest consumer of Artemia cysts…”

Traditional VS Modern

Viet-Uc started their hatchery operations in 2001. Today the company has nine shrimp hatchery units across Vietnam, supplying 15-20 billion postlarvae annually. This represents approximately 20% of the Vietnamese market share.

“We have been applying INVE’s SEP-Art technology since 2013, and we recently switched to their new CysTM 2.0 system. We have also upgraded our Artemia production room by redesigning the facilities and tank setup, upgrading our lighting and temperature control system, and implementing improved standard operating procedures. This has resulted in a more efficient production of Artemia by reducing the amount of tanks and consequently labor and resources. Today, Artemia is produced in only 20 tanks of 2.5 m³ and we are able to hatch 4.4 to 6.6kg cysts/time in each tank, compared to the previous setup where we utilized 160 tanks of 300 liters. This allowed us to reduce manpower and produce the same amount of live feed in a more efficient way”

In Mediterranean marine fish production, Artemia is still an important and preferred component in the feeding protocols of bass and bream, and is essential to produce good high-quality fry in a consistent and predictable way.

Philosofish, one of our customers in Greece explains further their experience with our technologies and protocol here.

“Most hatcheries use traditional hatching and harvesting methods. We use modern harvesting tools based on the SEP-Art technology to separate shells & cysts from the nauplii to obtain a pure & high-quality live feed.”

Testimonial from the Director of the Samut Sakhon Coastal Aquaculture Research and Development Centre, Department of Fisheries in Thailand.

Innovation

Brazil has 20 large marine shrimp hatcheries producing a total of 25 billion post larvae. The consumption is 20 tonnes of Artemia cysts per year of which 4 tonnes are locally produced in salt ponds. Christine Macedo (Area Manager of INVE Aquaculture do Brasil) described practices from two main hatcheries: Aquatec, which produces 2 billion post larvae/year and Tecmares, with a production of 3 billion post larvae/year. Both hatcheries, Aquatec & Tecmares, use the SEP- technology to separate the Artemia nauplii in an efficient way from the cysts.

Marcos Camara (Federal University of Rio Grande do Norte) and Cristine Macedo said most steps from disinfection to harvesting are in accordance with the standard operating procedures. Yet some opportunities for further improvements have been identified including standardization of cyst decapsulation, nauplii cold storage practices and feeding of the proper Artemia stage (Instar I and II).

Marcos Camara (Federal University of Rio Grande do Norte) and Cristine Macedo said most steps from disinfection to harvesting are in accordance with the standard operating procedures. Yet some opportunities for further improvements have been identified including standardization of cyst decapsulation, nauplii cold storage practices and feeding of the proper Artemia stage (Instar I and II).

For more information about Artemia cysts use in fish/crustacean hatcheries around the world visit, the Network of Aquaculture Centres in Asia-Pacific (NACA) webinar, click here.